Vas zanima študij pri nas?

Izpolnite spodnji obrazec za prijavo v program. V roku enega dneva vam bomo posredovali vse potrebne informacije o vpisu.

Mechanical Engineering

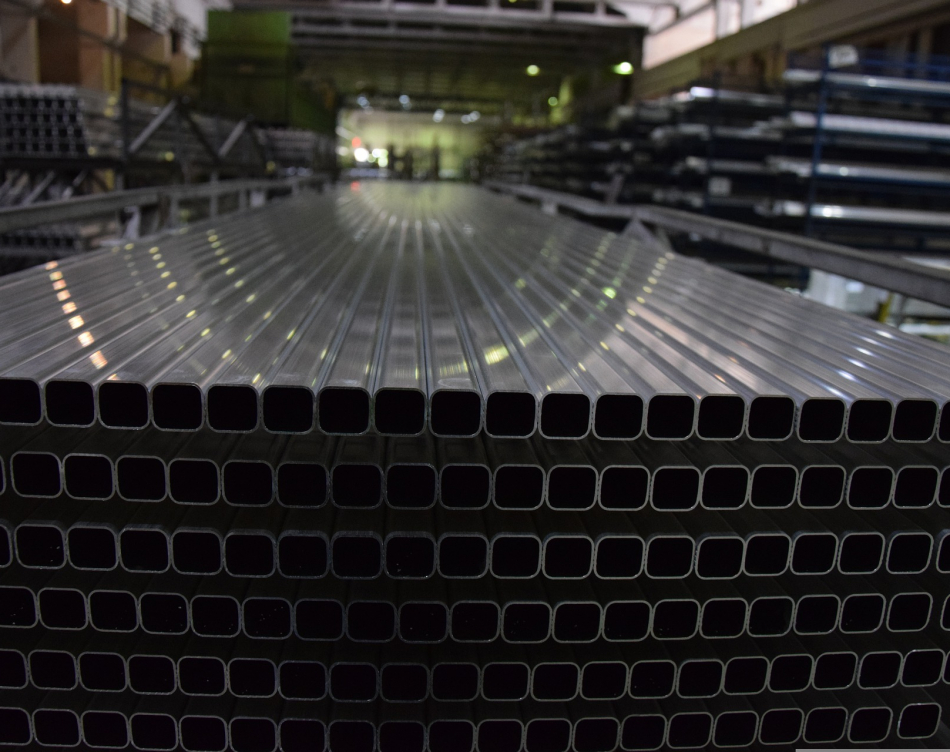

Aluminium is the metal of the future. Its uses know no bounds. It is used in one form or another in all sectors of the economy. It can be found in the household, where it is used for food packaging, in the construction, aerospace, automotive, space technology etc.

The transformation processes of aluminium alloys are carried out in several different ways such as rolling, kneading or forging, precisely because the casting combination of alloying elements gives the possibility of global applications.

In the industry of semi-finished metal products and products, it is also necessary to attribute supporting processes such as maintenance, rehabilitation and correction for the ongoing industrialisation.

In my thesis I will discuss the processes of aluminium alloys transformation for kneading and their application, which are the result of Impol’s research. I will pay more attention to the remediation of tools, as this is the work I do.

I will explain the different ways of using extrusion tools, the preparation of the storage, correction and cleaning of the tools, the machinery needed for this purpose and the problem of choosing the appropriate geometry of the extrusion tool.

The key purpose of the thesis is to explain the technology of the pickling process, the problem of usability, wear and efficiency and to set up some optimisation by reducing cycle times and consequently reducing costs.

With the help of process operators and analytical records I will compare the past state of the technological process with the new findings and define them with substantiated evidence for further workflow.

In this thesis I will test the effectiveness of ultrasound during the reaction process and finished cycles for more efficient disassembly of extrusion moulds. I will investigate the most efficient option for carrying out the work by varying the sorting and loading combinations of the tool into the system.

This would in turn relieve the operator of the burden of reducing cycle times and process quality costs.

The thesis was to be a kind of proof to a useful suggestion to the company where I am employed, when I proposed to rehabilitate the ultrasonic system to the status quo for a faster and more efficient deviation of Al-alloys from the tooling while saving on the quality of the liquor and subsequently the surface durability of the extrusion tooling.

The purpose of the thesis is to improve the quality and quantity of work in the process of cleaning of extrusion tools with sodium hydroxide using theoretical resources, research and practice.

The focus of the thesis is also on the safety and health awareness of the correct handling and performance of the pickling process for the operator whereby potential hazards in the pickling process could be avoided.