Vas zanima študij pri nas?

Izpolnite spodnji obrazec za prijavo v program. V roku enega dneva vam bomo posredovali vse potrebne informacije o vpisu.

Mechanical Engineering

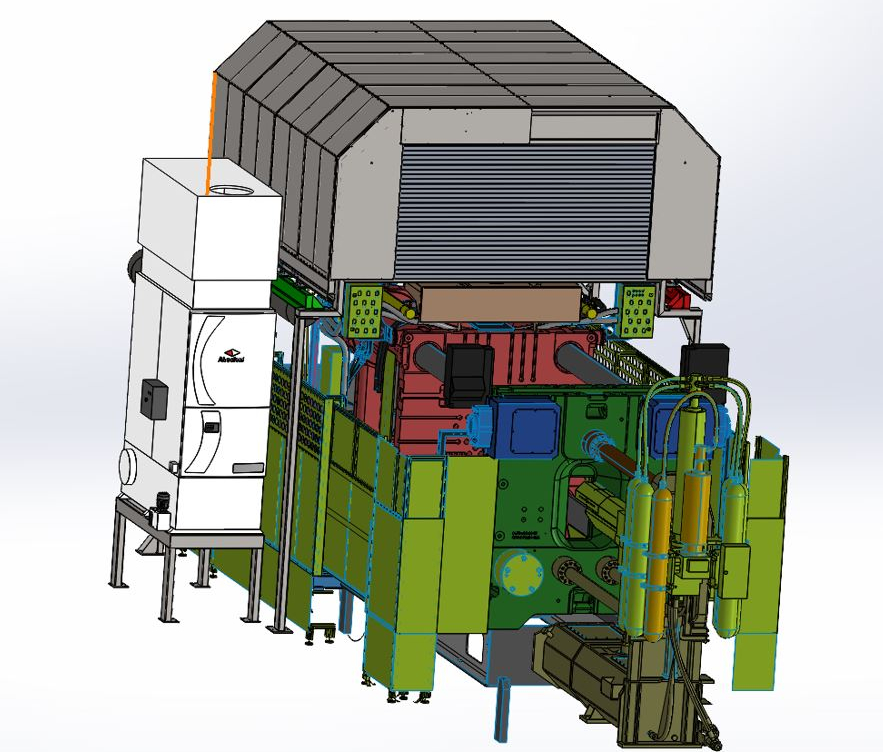

In the thesis we will get to know the course of the construction of the hood and the substructure for the extraction of emissions from foundry tools in the high-pressure casting of Al alloys. At the beginning of the thesis, we will describe the field of work and define the problem.

The purpose of the thesis is to improve the suction of emissions released during the coating of foundry tools. I will describe a company that breaks down by making nap and selling oil and lubricants.

I will present the importance and system of suction, in high-pressure casting, and what importance it has on the health of workers in production. Then we come to the presentations of devices that are present on the market, I will describe how the filter unit works, I will present the importance of the filter cassette and for which type of suction is used.

The high pressure die casting process (HPDC) is widely used to produce a wide range of products with high dimensional precision, producing thin-walled and highly detailed light alloy parts with high productivity.

We will describe the process of casting Al alloys by the high-pressure casting process. What equipment is used for casting. We will show the operation of a high-pressure machine with a hot and cold chamber.

In casting, the use of separating coatings for tools is very important because the surface of the die is cooled by spraying lubricant, here I will show what impact and importance it has in casting. We will also show the lubrication of tools in various casting processes.

In order to get the best way of filtration, we can dimension the hood according to some guidelines and calculations. I will show how to get a sufficient amount of air extraction in the hood and how to determine the size of the hood and the sub construction.

I used the SolidWorks computer tool for the design. Here I will show how the construction design of the hood and substructure works. We must keep in mind that assembly and transport are easy because it is important that the installation is done in the shortest possible time.

Maintenance is an important part in maintaining the life of the device and the hood, we will describe the course of maintenance of the hood and substructure. After the completion of the construction design, we will show the safety and ecological importance of the system of suction of harmful emissions.